Press Conversion • Lake Park Tool & Machine, Inc.

- 1. Less butt scrap. Since it takes fewer long billets to produce the same amount of extrusions, there is less butt scrap to deal with. For instance, three less billets per hour equals 15 less pounds of scrap per hour.

- 2. Less stretcher scrap. Producing the same number of

pounds with fewer billets also results in a corresponding

decrease in stretcher scrap. - 3. Optimization of extrusion lengths. The ability to handle billets 6" or 8" longer means the extrusion length can be optimized when you have a log shear or log saw in the press line.

Lake Park handles short-stroke conversions all the way from engineering to installation. Contact us for specific information

on your equipment.

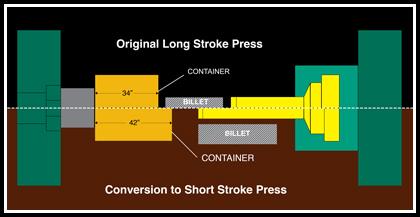

Converting an existing press to a short-stroke machine reduces

dead cycle time because heavy parts (main ram and moving

crosshead) do not have to be accelerated to a high speed and then quickly decelerated. In a short-stroke press the ram needs to move only a few inches to begin upset and extrusion. Furthermore, billet length can be increased by as much as 8” or more.

Typically, a 2500-ton press has an operating dead cycle of 20 to 24 seconds, depending upon the condition of the press and the

hydraulic and electrical systems. Suppose that press extrudes 8”

diameter by 30” long billets weighing 150 pounds at a rate of 22

billets per hour. With a butt scrap loss of one inch (five pounds), it

would average 3190 pounds per hour. If the press operated five

eight-hour days per week, in a fifty-week year it would push 44,000 billets or 6,380,000 pounds—but it would have 269 hours (6.7 weeks) of dead cycle time!

Convert that same machine to a short-stroke press, and it would

have a dead cycle of approximately 16 to 17 seconds. A decrease of one second increases production by 38,950 pounds per year, so an easily achievable decrease of only three seconds would increase production by 116,850 pounds per year!

In addition, there are several other advantages to longer billets: